Bookbinders were initially slow to adapt to the changes brought on by the adoption of printing in Europe; however, by the end of the 15th century parchment had given way to paper leaves and towards the middle of the 16th century English binders had made the transition from wood to paper-based boards. The introduction of the plough coincides with the use of paper based books. Fig. 2. Prior to that book edges were either left un-cut, or they were trimmed with the use of a draw-knife.

The traditional method for trimming the edges with a plough was to cut the leaves in-boards: the boards and the edges of the text-block were cut simultaneously, once the text-block had been rounded and after the boards were laced on. Ploughing edges is a technique still used today, though the practice of ploughing in-boards, is now very rare, even amongst craft bookbinders.

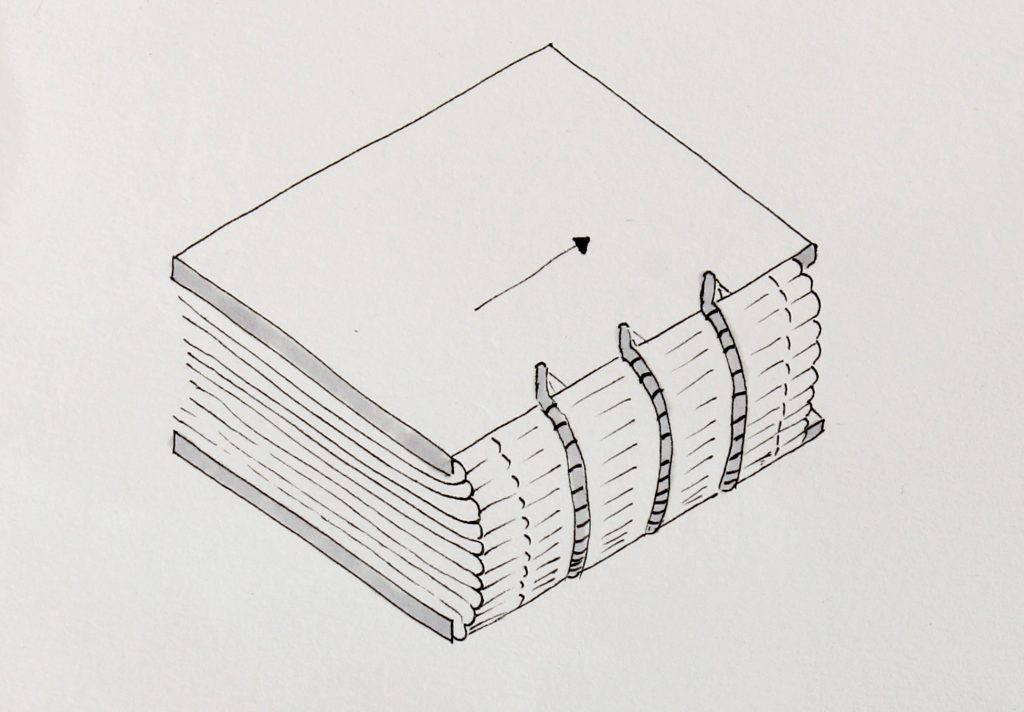

So how is trimming in-boards done? Trimming the head and tail in-boards is relatively straight forward. In-board bindings were laced on with enough movement at the joints that the text-block and the (oversized) boards could be cut whilst still preserving a square. The head is trimmed by placing the book in the laying press and shunting both boards down the requisite amount. Fig. 3. When the cut is finished the book is released from the press and boards are pushed back up into position, restoring the square. The tail is done in a similar fashion. It is worth noting that mediaeval wooden-board bindings with strong double supports did not have enough slack at the joints; likewise, the recent trend in fine binding for lacing on tapes would also not allow enough movement at the joints for trimming in-boards

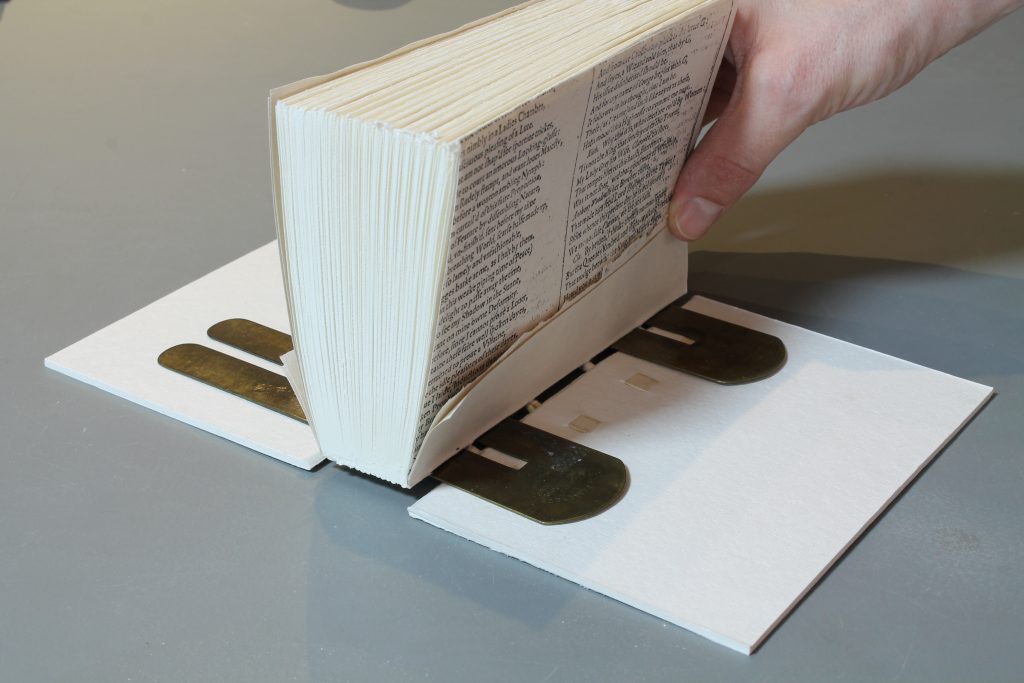

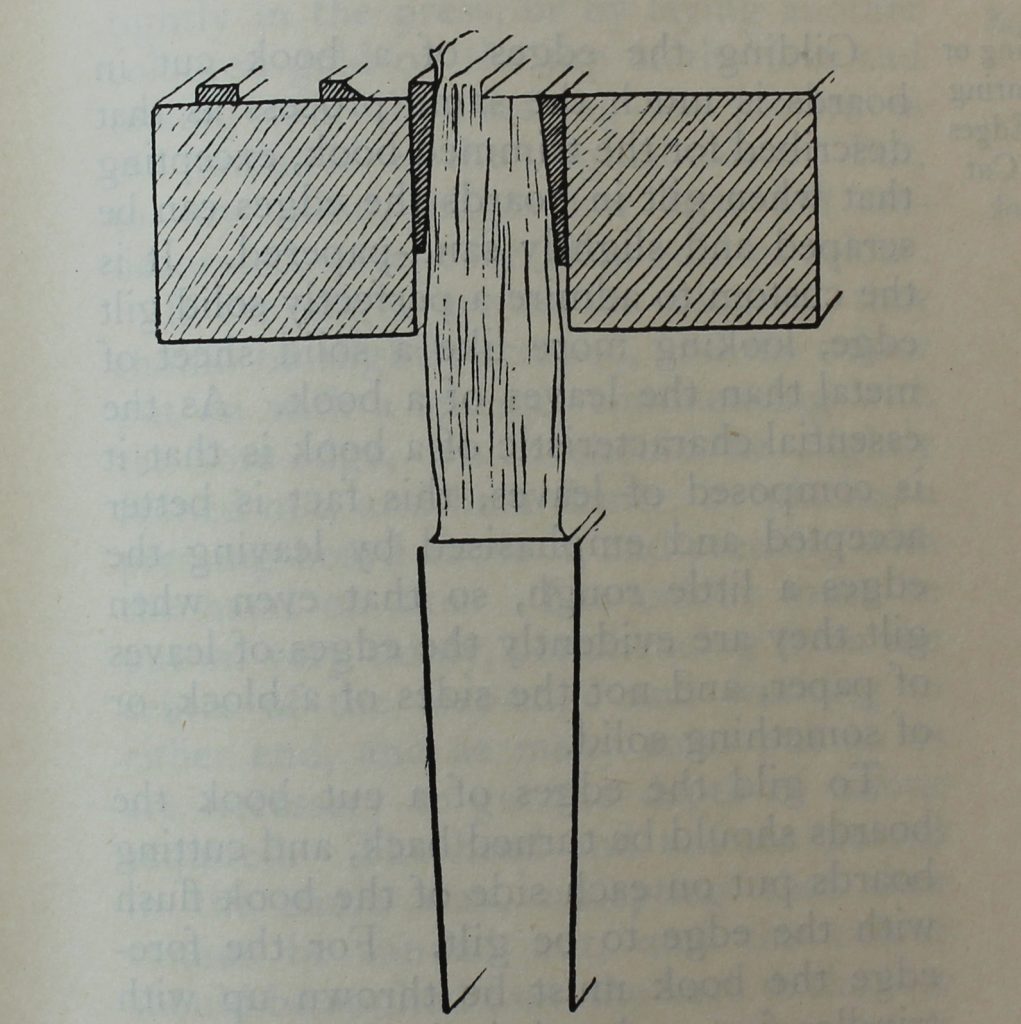

Cutting the fore-edge of the text-block requires the use of trindles. Figs. 4&5. The process is rather fiddly; it involves inserting trindles around the two outermost supports. The boards are opened right back then the tines of the trindles are inserted around the supports and through the joints (between the text-block and the boards). This forces the rounded spine back into a flat position, thus flattening the fore-edge. Once the book is in position – and held tightly between boards – the trindles can then be removed. The fore-edge of the board is cut to size separately, this can be done either before or after the fore-edge of the leaves has been trimmed.

In the 19th and 20th century iron pins were replaced by mass produced brass trindles. These are in-fact brass button polishers, used by the military and other uniformed trades to guard the garment whilst polishing. My set of trindles have the owner’s name and service number hand stamped on them and are possibly from the first world war. Fig. 1.

Arthur Green, First published 30th May 2018

I am pleased to announce that after further research on the subject, a more comprehensive version of my blog on trimming edges in-boards has been accepted for publication. Because of this, the original blog was amended on 13th July 2018 and replaced with a shortened version. Further information about the publication of my essay will be announced in due course.

Well done summary. What is the thickness of your trindles?

Hi Jeff,

Thanks for the positive response. Since posting the blog i have come across a few more references so will be publishing a revised version soon.

My Set of trindles is 0.7mm There are quite a few on eBay!

Arthur

I loved your article! Found it extremely interesting and well documented. I’m an argentine bookbinder, sorry for my poor english. Thank you very very much for sharing it! Best regards, Dina Adámoli

Dina,

I am glad you found it useful, thanks.

Arthur

Nice summing up on the technique and the somewhat understated “fiddly” comment – particularly doing a fore-edge between 2 cutting boards. A wrapping of cloth bandage/sheeting (head and tail) around the textblock to hold the trindle induced flat spine can be quite helpful with inserting into the laying press with 1 or 2 cutting boards. I prefer to use just one cutting board with waste board for blade to run into – not as the Cockerell illustration where the blade runs into the second cutting board. The waste board also assists if inserting into the laying press which is turned through 90 degrees. This is achieved by being a flat surface allowing control over the aligning of the cutting board with the laying press top surface.

Thanks for your comment. If you’re interested, Arthur’s essay on this subject will be published in Suave Mechanicals in early 2022.

Hi, and thank you for this informative article! I’m a mostly self-trained amateur bookbinder and am learning a lot from blogs like yours. I’ve only recently discovered the idea of trindles, and am wondering about how it would (or wouldn’t) affect the problem that comes from trimming before rounding, where “steps” are introduced as the signatures move together during the rounding process. Do you still have steps with this method?

Hi Patricia, this is a very good question. Trindles largely eliminate the problem of steps at the fore-edge, caused by rounding after cutting.