Introduction

For some time, I have been considering my choice of adhesive for gluing-up the spines of paper text-blocks. Traditionally protein-based animal glue was used but in the last few decades it is has fallen out of favour. Animal glue can be inconsistent, and can sometimes be brittle and stain the paper. Although still used by the trade, animal glue is now rarely used by fine binders and book conservators.[1] Animal glue has a number of desirable properties though; it sticks well, and on many occasions can be removed easily from old books without causing damage to the spine-folds.

Two adhesives that I have been using for gluing-up are: conservation grade wheat-starch paste and ethylene vinyl acetate, or EVA. Starch paste has been used for centuries; it can provide a reasonable adhesive bond but I have started to question whether it is strong enough for gluing-up large working books or those without strong sewing supports. Like many conservators, I avoid the use of synthetic white glues such as EVA and PVA when applied directly to the spine-folds of historic bindings[2]. I have, however, been using EVA for gluing-up the spines on new bindings because of its strong adhesive bond.

There has been increased interest recently in the use of conservation grade gelatine by conservators for a number of applications, so I wanted to revisit animal glue (or gelatine) for gluing-up. Gelatine is transparent and doesn’t contain any of the added ingredients found in animal glue, but can it offer strong adhesion and flexibility similar to that of white glues, as well as good longevity and reversibility?

Devising a test

The test I had in mind was to simulate gluing-up and adhering a spine lining on a springback binding. These are heavy working books which (usually) have only a single leather spine lining; therefore the binding relies heavily on the adhesion of the spine-folds to each other and to the leather lining.[3]

I chose to test GMW Photogelatine with a 280g bloom.[4] I had experience with this type of conservation grade gelatine for parchment repair so was hopeful that it would provide sufficient adhesion. I was also aware that James and Stuart Brockman have been using food grade gelatine for gluing-up. Stuart Brockman was kind enough to share his experience with me: he uses platinum food-grade gelatine. Interestingly platinum gelatine has a bloom grade of 235g -265g so not a lot less than the one I planned to test.

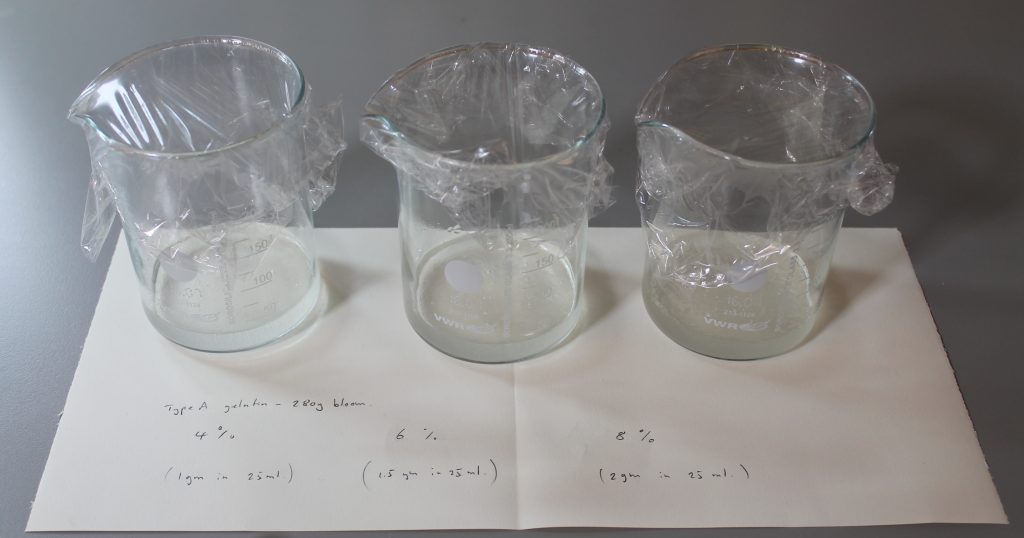

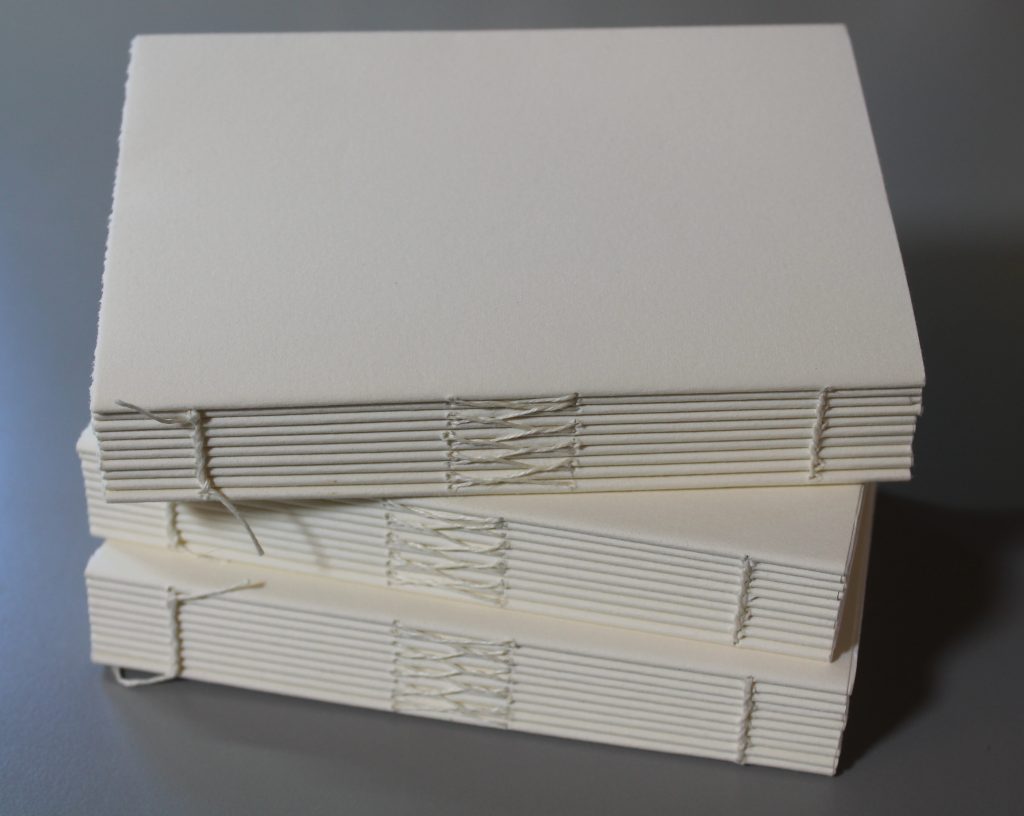

I decided to test the gelatine by gluing-up blank book-blocks with three concentrations: 4%, 6% and 8% solutions. A second question I had was whether gelatine would also be a suitable adhesive for applying leather spine linings, so for each of the models I would attach two linings: one with gelatine and one with wheat-starch paste for comparison.

Making up the adhesives

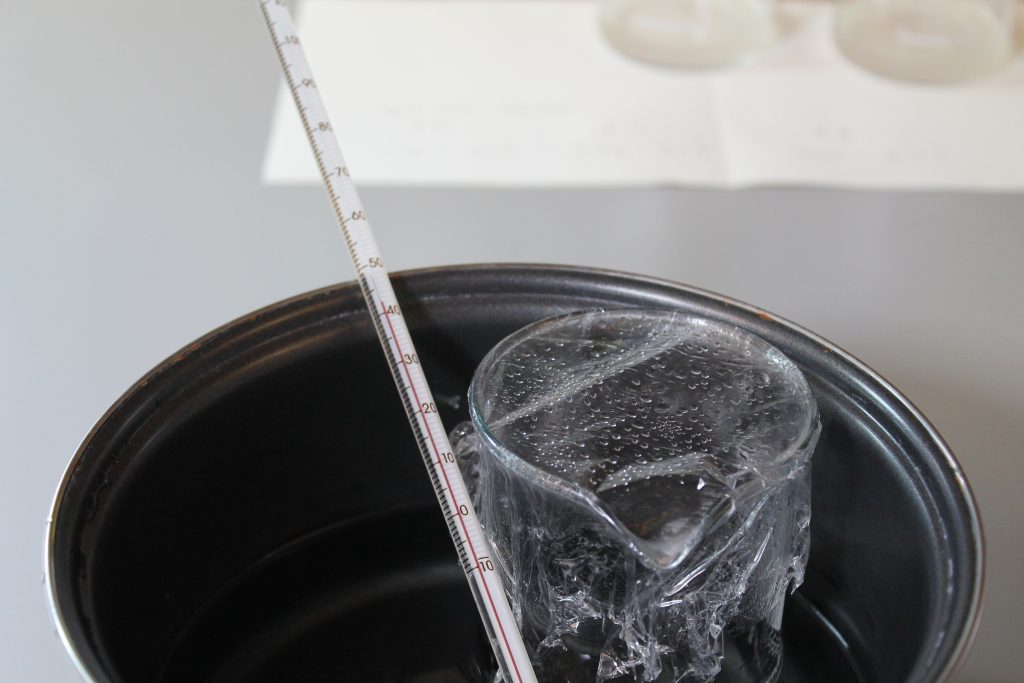

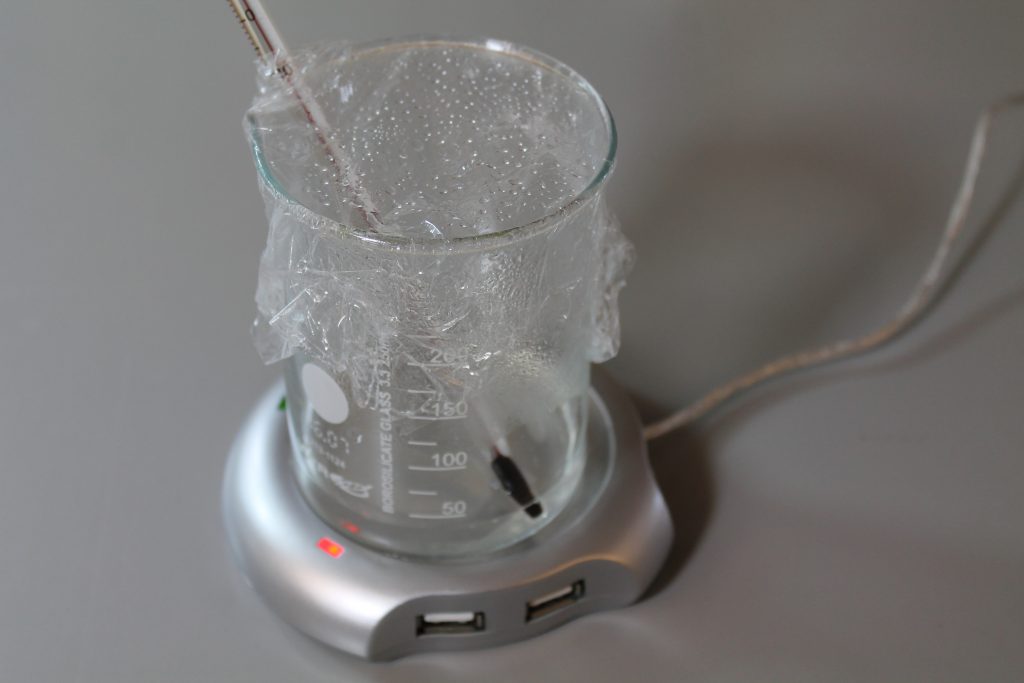

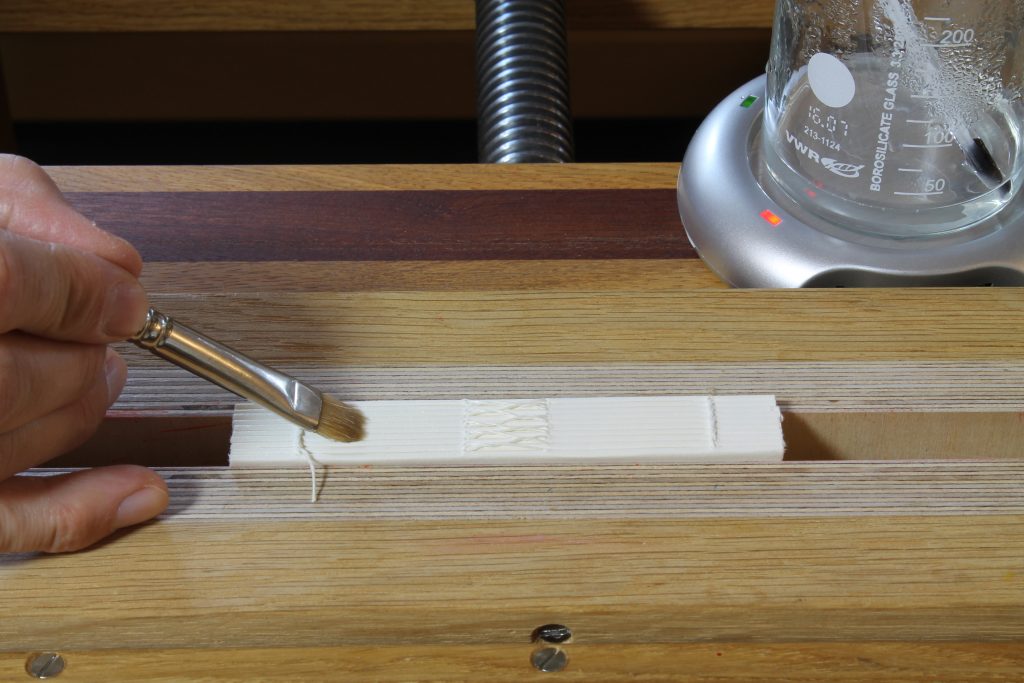

Warm liquid gelatine: three concentrations w/v in 25ml of water. Weigh out the gelatine granules: 4% (1gm), 6% (1.5gm) and 8% (2gm) and place in beakers. Add 25ml of water to each of the beakers. Cover and leave for an hour or two, or until the granules have swollen. Place the beakers in a pan of hot water (40-50oC) and stir until fully dissolved. Do not heat over 70oC or the gelatine will denature. The gelatine is then ready to use. A USB ‘mug-warmer’ can be used to keep the gelatine at a steady 37-40oC (and liquid) whilst in use.

Paste: a 1:4 v/v ratio (50ml in 200ml of water), cooked for 30 minutes in a saucepan and stirred by hand until glossy, and left to cool. Sieved three times and diluted down to slightly thicker than double cream, or until it only just forms peaks.

Method

- Prepare the adhesives as above.

- Three blank book-blocks of ten octavo sections were sewn together with an unsupported link stitch and then pressed.

- The backs of the sections were rubbed down to close up the gaps.

- Gluing-up: a thin even layer of gelatine was brushed onto the spines then left to dry.

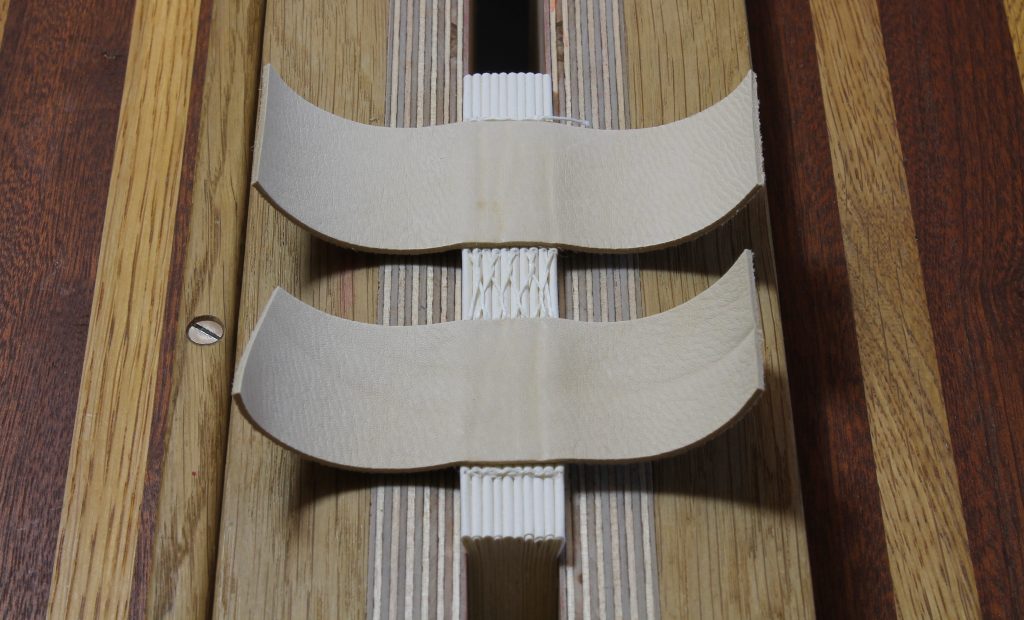

- Two leather linings were attached to each model: one with paste and one with gelatine (the same percentage as that used to glue-up). The linings were pasted (or glued) out, left for a few minutes and pasted out again. They were then stuck to the spine and rubbed down with a folder and left to dry fully overnight.

Materials

- Sections: made up from St Cuthberts Mill, Somerset Book, off-white 115gsm.[5]

- Leather: J. Hewit & Sons, Archival BV repair calf. Chosen for its archival qualities but also because it is available in a thickness suitable for spine linings i.e. 1.2mm – 1.5mm

- Gelatine: GMW Photogelatine Type 2, 280g bloom

- Paste: VWR wheat starch.

- Mug-warner: bought from eBay for not much money.

Results

All three concentrations of gelatine were successful in that they all stuck the sections together, and the sections remained stuck when the books were opened. The 8% solution had a higher viscosity (similar to thin wallpaper paste) so it proved easier to apply an even layer. Pure gelatine has a relatively short open-time compared to animal glue; I found that when the gelatine was pasted (or brushed) out then it cooled on contact and solidified. This didn’t prove to be a problem when gluing-up the sections as only a small area of the spine was glued at a time; however, adhering a larger area in one go – such as a large leather lining – would have been difficult. Both the paste and all three concentrations of gelatine stuck the leather linings well with little discernable difference. I tried peeling the leather linings off and all were well stuck to the backs of the sections. Paste would be my preferred adhesive for adhering the leather lining because of the longer open-time and easier application.

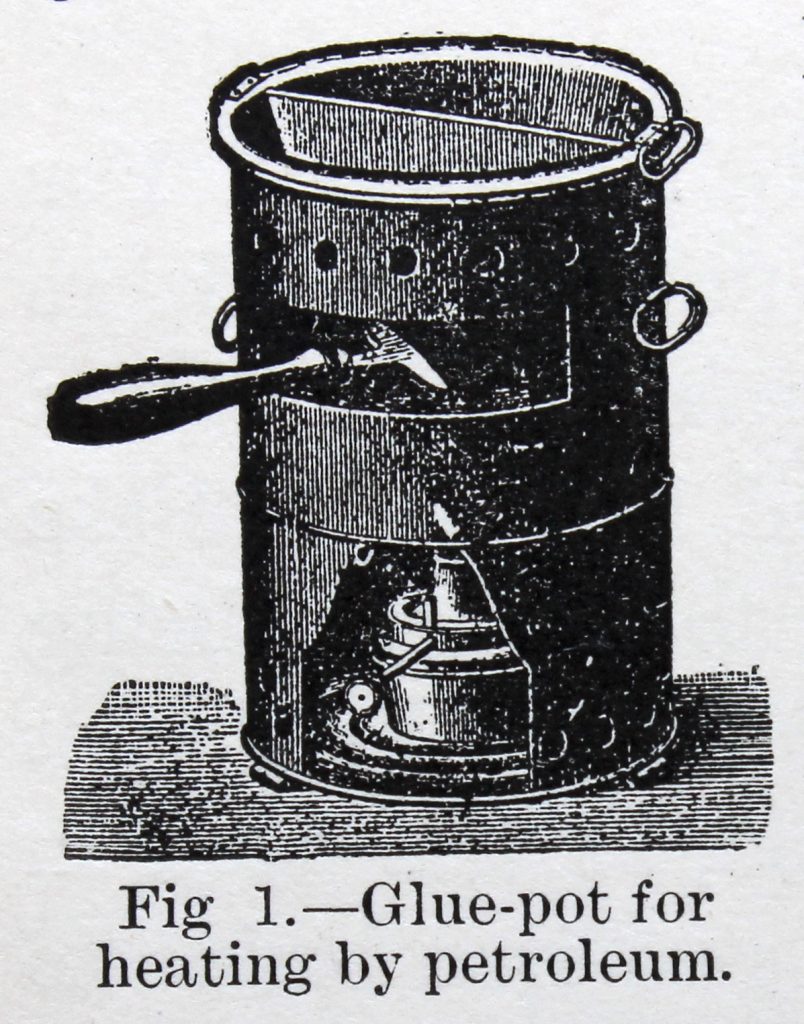

Keeping gelatine (or animal glue) warm is an added complication. This was traditionally done with the use of a double-boiler or glue-pot. Setting this up for a single book or a short run is more time consuming when compared to cold white glues. Could it be that this extra work is one of the reasons that it’s not used more? The preparation of the photogelatine didn’t prove too onerous and a USB mug-warmer (rather than a glue pot) did simplify the process. If covered and stored in a fridge, gelatine will keep for about five days so is comparable to wheat-starch paste in that respect.

All that is necessary when gluing-up is that a small amount of adhesive is applied between each section to hold them together, so any glue on the back of the spine-folds is superfluous. Thick amounts of glue on the spine can regulate the opening i.e. make the spine more resistant, but ideally this should be achieved with the use of spine linings (or sewing) rather than loads of glue. That considered, I was pleased with the function of each of the three models. The leather was well attached and did its job in regulating the opening and the thin application of glue meant no cracking or lifting.

Conclusion

I am aware that the use of gelatine for gluing-up is not new; A. J. Vaughan suggests its use in 1929 and the Brockmans have been using it for decades, but its use doesn’t appear to have become wide-spread.[6] Whilst this was only a small-scale test, I am spurred on by the positive results and will experiment further with gelatine for gluing-up.

[1]This is based on my own experience in the UK. I’d be interested to hear if other countries use animal glue or gelatine for hand bookbinding.

[2]EVA is a versatile conservation adhesive and I am not against its use for other applications where not in direct contact with book leaves.

[3]The leather linings on springback bindings are traditionally referred to as ‘clothings’. I am yet to discover why this is the case?

[4]Bloom is a test to measure the strength of gelatin, originally developed and patented by Oscar T. Bloom in 1925. The test determines the weight in grams needed for a 12.5mm diameter plunger to depress the surface of a 6.6% w/v gel 4 mm (at 10oC)without breaking it. The result is expressed in Bloom grades.

[5]I use this paper for all of my book models; using the same paper enables easier comparisons.

[6]Vaughan, Alex J. (1929) p. 109 Modern Bookbinding

Arthur Green, 17th August 2018

Thanks a lot for your inspirational article. I am researching environmentally friendly diy methods/materials for home and school use. For binding simple booklets hotmelt glue or EVA is widely suggested. I wish to avoid all non-degradeable polymers. However, woodworking got me to aquire some clear grade hide glue. It is excellent for indoor use in woodworking. As you suggest, a epilation wax warmer is cheap and easy to use. Small dropper plastic bottles filled with glue is conserved by deep freezing and thaw quickly in hot water. For glueibg booklet spines, I thought it would crack after use. Now I will certainly try! If this fails, starch is also on the list.

Best regards,

Marius Bunes

Norway.

During my handbookbinding apprenticeship in Germany (2009-2012) we used animal glue on almost all the books we bound to stabilise the rounded backs of the book bocks. It was never directly used on the paper though. We used PVA for lumbeck bindings or for a first back glueing on sewn book blocks and then put a thin layer of animal glue onto it.

We didn’t do restaurations, most work was year books of lawyer’s magazines, thesis binding, things like that.

But I don’t think that using animal standard procedure in binderies in Germany either. It was a third generation bindery and the owner was quite fond of some traditional ways of doing things.