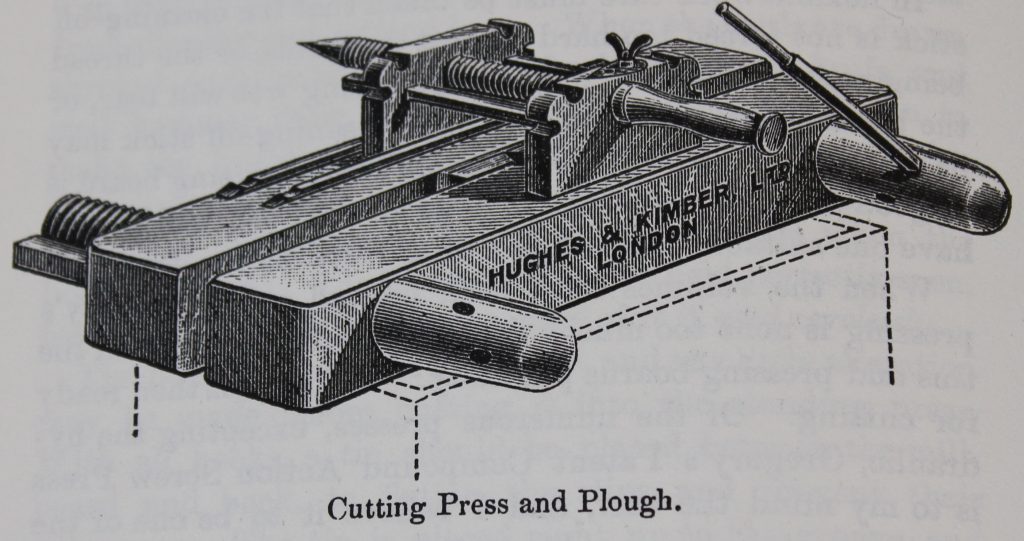

I just bought this beautiful antique plough. Sadly I don’t have any information about it’s provenance; however, it’s almost identical to the one featured in Zaehnsdorf’s ‘The Art of Bookbinding’, it even has the same teardrop shaped brass plate under the wing-nut. The blade of the plough has an ‘N. J. Hill London’ makers-mark engraved on the underside, so I would guess that it’s at least 130 years old? It has a few worm holes but is otherwise in great condition, so is still a very useable tool. I do have a slight moral dilemma as I have an Olive and Oak laying press which has a single runner baton (rather than the two batons as featured in the engraving above) so to use the plough I would have to cut a slot in the base of the left cheek if I want to use this plough in anger.

Arthur Green, January 2019

Hi Arthur,

Thanks for sharing the photo of your new plough. Personally I certainly wouldn’t cut a grove in this plough. Plus I don’t think you need to. I think if you use it carefully it will work fine with the single runner. Just keep some pressure pushing the left side into the runner. While cutting the force from the blade will provide that force (I think).

Or you could add a second runner like in the TAoB diagram. I think there would be enough clearance it wouldn’t interfere with the plough that came with the Olive and Oak.

I bought a second hand Wiesner lying press and tub last year and it didn’t have a plough or the runners. Luckily Frank lives nearby, so I bought a plough from him and he added the runners. Of course he had a heap made up and it only took him 10 minutes to add them. Maybe you want another lying press just for this plough. Frank would certainly space the runners to fit. I’m not serious with this suggestion. But here’s some photos for fun.

https://bookbindingaustralia.com.au/product-category/tools-hardware/wooden-equipment/

Trevor Lloyd uses a lot of Frank’s gear, and I know there is photo on the web of him using Frank’s plough, but can’t find it now. Here’s one with the press.

http://www.trevorlloyd.co.uk/articles_mg/articles_mg_01.html

I’m very envious of your purchase:)

Yours,

Darryn

Hi Darryn,

Thanks for taking the time to reply.

I think that i’ll probably leave the plough for now – it would be a shame to alter such a nice example.

I did try and use it as you suggested: sliding it up against the single runner but it moved about too much. However, a simple solution was to temporarily clamp a baton to the press to provide a second runner – this seemed to work well.

All the best, Arthur

Hi Arthur,

Nice article !

I would be interested to hear how it compares with plough from Olive & Oak, pros and cons.

Royston

Hi Roy. The original plough supplied by Jim was not made by him; the blade on this wasn’t great so i had to have another made, also the clearance isn’t enough – only 16mm, compared to 65mm on my Victorian plough. I think that a lot of the new ploughs on the market are made by people who have never used one! Jim’s on the other hand looks really well thought through. When i get hold of one I’ll let you know what i think.

Trying to reduce items in my loft,I recently brought down a cutting press and plough identical to yours.

Both press and plough are marked N J Hill & Co London E C .

I am open to reasonable offers from anyone who could collect and have use for these items.

Collection from near Dover Kent.

P S No Worm

For many years now I have referred to this style as a “Snail’s-Horn” plough, from the shape of the decorations. I have one that is effectively identical to yours, right down to the asymmetric casting of the brass wing nut. Hill/Hampson Bettridge snails-horn ploughs are comparatively common in America, and show little if any variation. Images first appear around the 1880s, in Crane, the second edition of Zaehnsdorff, and in an 1892 Harrild catalogue. Unfortunately there seem to be no images of English ploughs for about thirty years before Crane. The Hill/HB catalogues showed exactly the same image up until the eve of World War 2, and although this may have been due to re-use of old zinco blocks, I believe that there was absolutely no change in that period.

The Hill-Hampson Bettridge plant was bombed during WW2, and after the war they did a bit of cosmetic change to their plough design: the snail’s-horn cutouts were replaced by rounded-over quarter-circles, and the old presumably shellac finish (which normally darkens and reddens with age) was replaced with a presumably nitrocellulose laquer which preserves the wood’s original pale tan. The sturdy and manipulatable blade-holding mechanism was retained; in my opinion this is one of the main advantages of a good English plough over the over-engineered and under-thought French and American varieties My teacher, Anne Henning Kahle, bought this style of plough and lying press new from H/HB around 1960, and they are still going strong despite half a century of use in an active binding school where every student was taught to use them on every book (to master the technique, not because all books should be trimmed). The press had an eighth-inch deep rut worn in it by the 1970s, when it was planed down and reduced in height by that much; it now needs to be resurfaced again, or better to have a beech patch glued in and leveled. I resoled the all-wood cheek of the plough twice beginning in the 1980s, and it too now needs re-treatment; interestingly, the sole of the blade-holding cheek has not worn down at all, even at the ends. I watched the progress of wear on this plough and press for well over thirty years, going in to help with teaching after I had ceased to pay for lessons.

Another local binder, an English amateur, has an almost identical post-WW2 H/HB plough, except that it was made with a classic bolt knife, not a sliding knife! I have a similar coelocanth, a late-made Hickok American plough that is absolutely typical of their smaller model except that it has a classic forged bolt knife; though perhaps my plough was retrofitted. Neither Hill/Hampson Bettridge nor Hickok offered bolt knives as options in their twentieth-century catalogs. It is interesting that some demand for the blade style seems to have persisted.

With my experience of how rapidly ploughs wear, not just the soles but in the accumulation of “slop” and general wear, I would be inclined to regard any English plough still in usable condition as being twentieth century, and probably no older than the 1920s. And probably not1930s: who would have been buying ploughs in the depths of the Greqt Depression?. So: an age more like like 90 years+ than 130+, at least for mine. Whatever the age, my Hill/Hampson Bettridge plough is the gem of my plough collection.

Nathaniel Hill was my great grandfather on my mothers side. I know precious little about him apart from the fact he was in that trade for a long time, succeeding his father, also N.J. Hill. I suspect illness may have had a hand in him disposing of the firm , as records and family recollections say that he died in early 1914, after catching a chill whilst on the train to his home at 12 Winterwell Road, Brixton, which in turn aggravated long standing emphysaema. He passed away at home. His elder daughter married my WW1 AIF soldier grandfather and emigrated to Australia. Its wonderful to see some of his handiwork at last. Ive never seen any of it. Thank you.

Made by my great grand father or great great grand father, both Names Nathaniel J Hill. My grandfather married into the family in 1919 when he was on furlough after WW!. Thank you so much for allowing me to see his work